Thought Leadership

Robotic Liquid Handling: Lab Automation with Micro-stepping Motors

Robotic liquid handling has the power to transform the life sciences by reducing or eliminating repetitive manual tasks (and the errors that come with them) through automation. Entrusting high precision, time-consuming tasks to a liquid handling robot can empower scientists or technicians to focus on innovation, research, and face-to-face medical care rather than rote tasks.

For example, medical testing, analytical chemistry, and biological experimentation are three critical life science applications that require frequent pipetting. Pipetting is the process of suctioning (or aspirating) a small amount of liquid into a syringe, moving the sample to another receptacle, and then dispensing the sample in precise quantities into the second receptacle. Scientists, lab, and medical technicians can spend hours every day performing this simple, tedious task—a manual process that is prone to errors.

This is especially pertinent in the medical field, where errors can result in negative patient outcomes or even death while improved accuracy and diagnostic efficiency can save a life. With the advent of low cost stepper motors, liquid handling robots are now cost-effective and compact enough to be found in even the smallest laboratory or medical office. By decentralizing medical testing, robotic liquid handling can help democratize healthcare access and mitigate the growing workforce gap in this industry.

ADI Trinamic™ solutions enable accurate and vibration-free position control, an essential capability in robotic liquid handling. Higher microstepping and S-shaped acceleration enable laboratory equipment to optimize more tasks for higher accuracy and efficiency levels. ADI Trinamic solutions offer a flexible architecture, ease of implementation, and low maintenance reliability for life science applications.

Customer Success Story

Recently a lab automation developer turned to ADI Trinamic solutions for assistance with the design of their new liquid handling robot targeted at small labs, remote field locations, and individual medical offices. The system was designed for low cost and minimal footprint while satisfying the same precision requirements of more expensive pipetting robots used in large laboratories.

By reducing both cost and footprint, this new system now delivers pipetting robotics for rapid point-of-care testing applications in decentralized settings. Quantitative polymerase chain reaction (qPCR) is a widely used technique in which liquid DNA samples are precisely apportioned into pipette beakers to detect and isolate infectious disease strains (influenza-typing, for instance), bacteria contamination in food, or the presence of genetically modified organisms. Unlike traditional PCR, qPCR uses fluorescent labeling to highlight DNA sequences of interest. Advanced precision sensing enables highly accurate, real-time data collection. Decentralizing this capability makes necessary medical care accessible to more people, especially in the face of an overwhelming medical event like COVID-19 that placed impossible demands on centralized healthcare infrastructure.

Building a Better Liquid Handling Robot

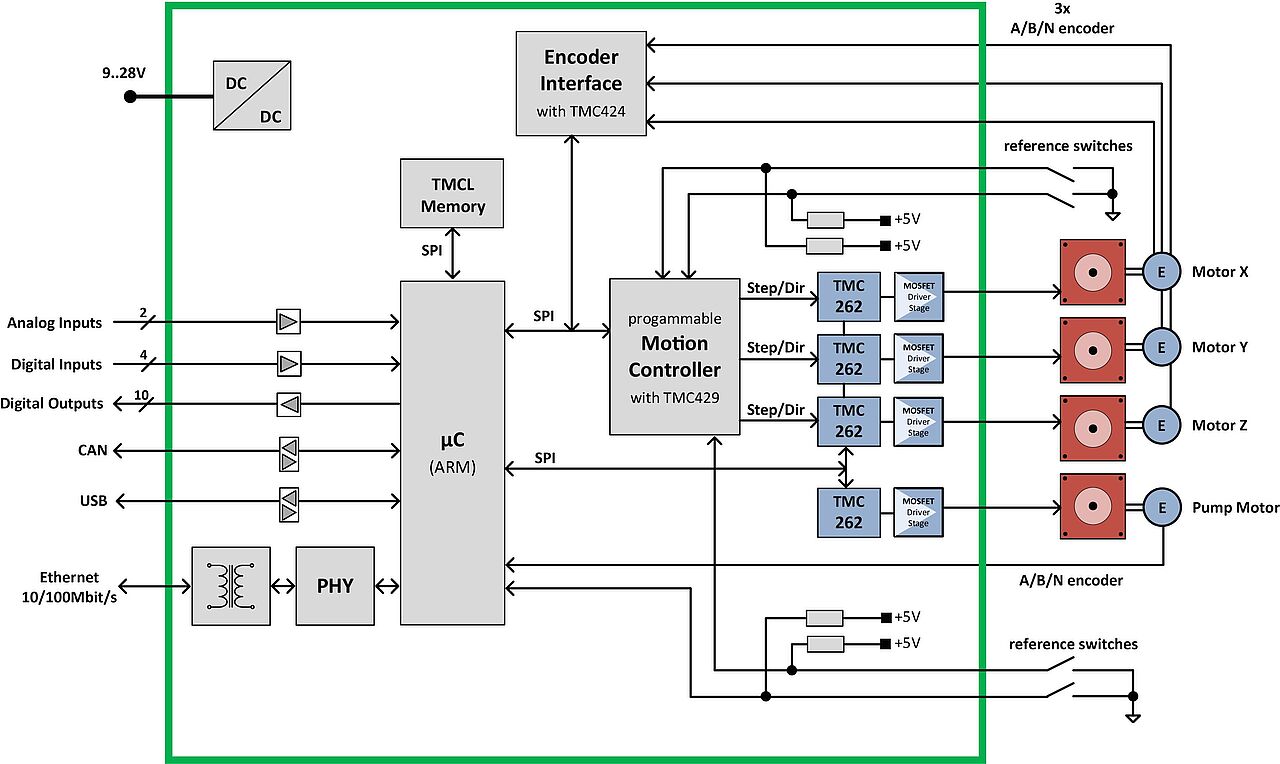

Working closely with its customer’s engineers, the ADI Trinamic team developed a custom motion control board that incorporates a triple-axis motion controller, a feedback resolution encoder, and four microstepping motor drivers. The compact and easily fabricated board design enables the system to deliver precise, vibration-free, three-dimensional pipette arm motion with an office-friendly noise figure of less than 50 dB. The use of ADI Trinamic solutions’ power-efficient ICs enables the system to operate without a cooling fan, reducing maintenance costs while eliminating a source of sound and vibration.

ADI Trinamic solutions further assisted the customer in reducing time to market for the system by leveraging one of our trusted manufacturing partnerships.

Maximize Efficiency. Minimize Errors.

Stepper motors have proven ideal for managing the precise three-dimensional movement of robotic arms, as well as the even more demanding precision required for liquid aspiration and dispensing through the pipette syringe pump. By automating the pipetting function, liquid handing robots significantly increase staff safety, experimental repeatability, error avoidance, and operational throughput.

ADI Trinamic solutions facilitate easy interface to microcontroller units (MCUs), including ADI’s fast and low power artificial intelligence (AI) MCUs. AI can further enhance laboratory optimization by leveraging real-time sensor data to control the movement of laboratory equipment. Whatever material your robot needs to handle, ADI Trinamic solutions can help it do so with the utmost precision and efficiency.